I’ll get right to it. Ducts leak 20-30% on average and that is many times even after typical sealing has been completed. The amount of duct leakage worsens as the home ages and typical sealing solutions degrade. There are a few ways to further seal them up but this innovative method takes you beyond mastic and duct tape. We are talking about Aeroseal and if you aren’t familiar with the name then you will be after this. While duct tape and mastic work by sealing the ducts from the outside, Aeroseal works by sealing the ducts from the inside. When people talk about home renovations, remodeling, upgrades or any other name for putting money into their home, ducts are likely not in the conversation. Heck, I know they weren’t high on my priority list. I’d much rather have granite countertops, sparkling hardwood floors, new tile in my bathroom, new doors and windows, appliances, furniture, etc., but my mindset has shifted a little now that I have a kiddo on the way and a family to worry about.

The previously listed investments are all things that we can see and enjoy every day with our eyes, that make an impact for anyone in our homes, and we take instant pride over how great it looks. The duct work is out of sight so maybe that’s why we don’t prioritize it as much as it should be. The floors and countertops look nice but that’s about it, the furniture adds comfort so that’s comparable in one way to what your ductwork provides, appliances go along with cleanliness and health as they give you a convenient way of storing food then cooking it and cleaning the dishes you ate on, doors and windows add comfort and keep your air healthy so that’s a little more comparable. But really, doors and windows are the closest thing to positively affecting your health compared to your ductwork. Why? If ductwork is leaky then you are opening up more opportunity for poor IAQ, or indoor air quality. Returns are notoriously leaky and since they are under negative pressure, pulling air back to the system, each leak will drag in whatever is behind it and circulate it in the system. This means dust, insulation fibers, dirt, humidity, pollen, allergens, etc., will be plaguing your home and increase you and your families development of future health issues. This isn’t good for adults but even worse for newborns/infants or anyone that already suffers from allergies or respiratory concerns. The negative pressure can also create backdrafting of combustible appliances which can increase the CO content in your home along with odors. And while supplies are known for simply pushing air, as the name implies, they too pull in dirty air through an effect known as the Venturi Effect. This happens almost regularly around the sheetrock or baseboard to register connections where if you pop off the register you will likely find an opening or space around the entire thing. So maybe instead of your next big investment being on something you can only appreciate with your eyes, focus on a project like duct sealing that will have a lasting impact on you and your families health and comfort plus energy savings.

A Better Solution

Maybe the biggest pushback I can find with Aeroseal is justifying the cost. The national average to have a home sealed with Aeroseal is just over $2k which might sound like a lot compared to simple duct tape and paint on mastic. If you really look at it as the long term solution that duct sealing in general is meant to be then the investment quickly begins to make sense. The catch is you really aren’t comparing apples to apples. Let’s break down just how Aeroseal excels beyond the competition.

Peace of Mind

The cost of having your ducts sealed is backed by a 10 year manufacturer warranty, plus in many cases will include additional warranty coverage that the service provider has included in the deal. Basically, Aeroseal is so confident in their product that they guarantee the effectiveness of the solution and will “bite the bullet” themselves if any rework is required. The 10 year warranty isn’t to say that the solution is only good for 10 years, just look at cars that offer 3-5 year warranties but are driven for a decade or longer. Unfortunately, while vehicle brands have fairly comparable warranties from one to another, good luck finding someone to warrant duct sealing with mastic or duct tape longer than a year. The Aeroseal solution has gone through extensive testing that shows it to hold up for greater than 30 years. Both mastic and duct tape will degrade over this same period of time and require reapplication to ensure its effectiveness. Some research even shows that 5 years is about when you will need to reapply mastic to maintain the results which further increases the cost of your duct sealing investment; basically it might be a cheaper solution up front but rework will cost you in the end.

Get It Right the First Time

This is a truly test in, test out procedure and the testing is included in the cost. Mastic and duct tape might be cheap as just products but when you start adding in the testing to verify duct leakage and prove results it will add costs, both in the form of added services and labor. It’s also important to note that since Aeroseal is managed through software that is integrated into the testing equipment, it is fool proof and ensures consistency. It can also be applied over duct work with some dust build up although it is recommended to clean the duct work prior to sealing, and then don’t worry about cleaning them since your duct work will be tight. Mastic and Duct Tape require a little more skill/consistency on the technician which leads to more opportunity for human failure. The mastic should be applied evenly and thick but the quality of the job is a direct reflection on experience and steadiness of one’s hand. Duct tape should be applied to a clean surface to ensure it adheres to the duct work which is an easy skip over if the contractor is in a time crunch. With Aeroseal, you know what results you will get; there is no guessing. Mastic and Duct Tape can get you the results with a quality job, it’s not impossible and is still an effective solution, but its success cannot be guaranteed in the same way as Aeroseal.

Save Money and Time

Speaking of labor, an Aeroseal job is done in less than a day for the majority of homes with the prep work taking up most of the time. The only requirement is to go around the home and plug off the supply and return vents plus the internal components of the system such as the coil with foam blocks so the duct work can be properly pressurized and the aerosolized sealant won’t spray into your home. Filters, otherwise known as “scrubber fans” will be added throughout the house as a secondary layer of protection and these will suck any airborne particles/sealant to it so you can have peace of mind knowing all your furniture, art work, carpet/floors, etc. won’t be covered in the sealant. The time it would take to seal ducts with traditional methods, to the level of tightness Aeroseal offers, would take longer than a day and could cost you more in just labor alone especially when it comes to inaccessible areas that we will touch on later.

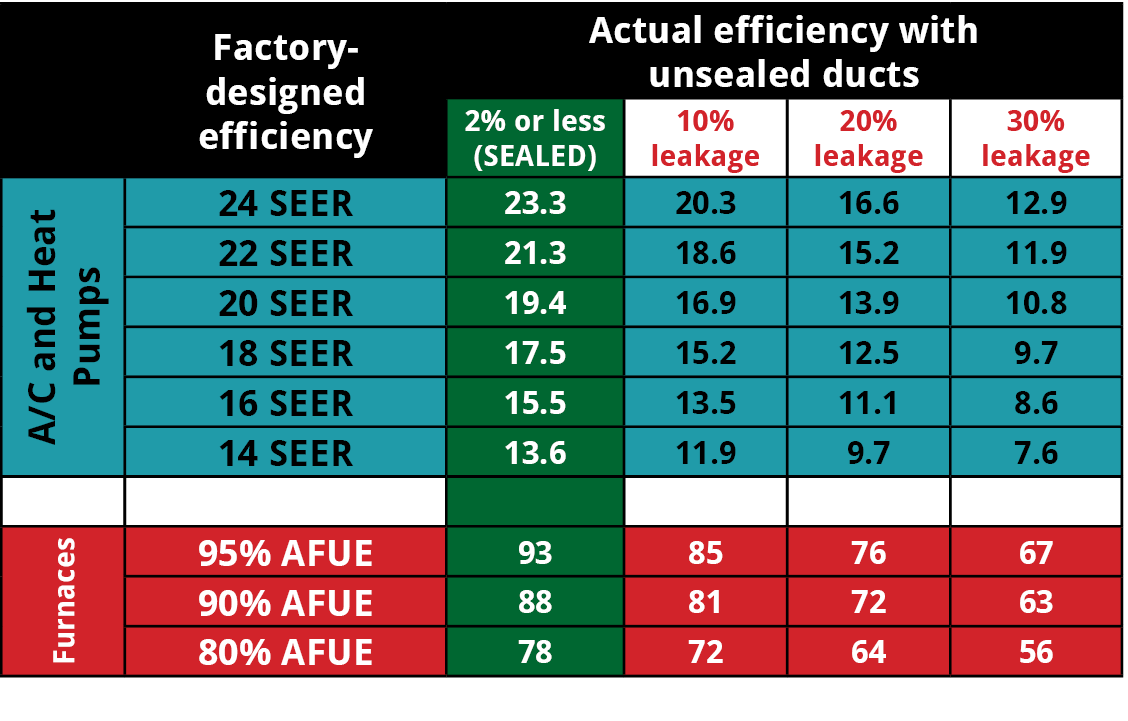

It also amazes me when I hear people debate about the significance of duct sealing. I think we can all agree, or most of us can buy into, that every degree you turn your A/C up in the summer or furnace down in the winter correlates to an energy savings. It’s an easy argument; when your system works less by turning down the requirement at the thermostat you are consuming less energy since your system works less and less energy use means lower energy bills. So that’s easy, but for some reason when you talk duct leakage it doesn’t translate that easy. When ducts leak you are losing efficiency by not allowing the proper amount of CFM’s to travel to each room. When this happens, homeowners will begin altering their thermostat settings to get the results they want by turning the air down in the summer or up in the winter and that increases your energy bill. It also means that if you leave the thermostat setting alone it will take you longer than it would if the ducts were sealed to reach the temperature you have selected, meaning longer run times and more wear on your equipment. This is even worse when leakage is outside of the thermal envelope and the duct leakage is going to a space that you don’t even use such as the basement, crawl space, inside of walls to the outside, or the attic. The SEER rating chart above shows you the significant impact that leakage has on the performance of your equiment. Picture a water hose hooked up to a sprinkler for your lawn and the water hose has many tiny holes throughout it. Not only do you lose pressure at the end of the hose so the sprinkler isn’t reaching areas it otherwise could but you are watering areas along the path of that hose that you may not be concerned with. No one in their right mind would continue using a leaky water hose so why continue using leaky ductwork?

Seal Everything Without Turning Your Home Into Ground Zero

No need for tearing anything apart to reach the leaks. Ducts tucked behind drywall ceilings in the basement, up in the attic, panned in returns behind drywall, insulation wrapped around ductwork, etc. can stay just how it is and be sealed. Many times the insulation wrapped ductwork looks sharp and professional but a quick look through an infrared camera will likely reveal that the ductwork underneath was not sealed. Don’t think for a second that because its wrapped in something that the leakage doesnt exist or doesnt have an effect. It goes right back to the holes in a hose analogy and all you are doing is putting conditioned air where you dont want. This benefit cuts down on added costs and labor time since you wont be tearing up drywall or removing insulation around the duct work to get to the leaks. You also get ALL of the leaks, not just the ones you see or think you see. Every single metal on metal connection leaks unless it’s sealed and not all of those connections get sealed as it is. These are areas like in 90 degree bends that have a bunch of metal on metal joints that allow you to twist and position; very convenient sure but very leaky. Every one of those transverse seams, where the metal is pushed in and connected with the next, leaks. The longitudinal seams where the sheet metal is folded over to create a box leak. Even though it looks tight and neat, air moves through very tiny spaces… especially when positive pressure is being added on the supply side which motivates the air to leave through leaks.

Another thing that seems to come up often is whether it’s a better idea to simply install brand new duct work instead of having it sealed. While that is a genuine concern and could be your only answer, most situations do not call for all new duct work. But if you must, all new duct work will require your home becoming a construction site, cost on average anywhere from $35-55 a linear foot and more than likely still leave you with additional duct leakage that Aerosesal could have gotten. A typical home will cost anywhere from $1,000 – $5,000 for all new duct work depending on size and complexity, so Aerseal’s ~$2,000 average still doesn’t seem so bad when you don’t need to turn your home into a construction site, you could leave for work and return with your ducts sealed and never know anyone was there (except for noticing more air flow), and the results are guaranteed.

Strength in Numbers

Another big concern is how big of a hole Aeroseal is capable of sealing. They rate the product to seal up to a 5/8” hole. For those who have drilled a 5/8” hole into anything before you may have mixed feelings on if that is big or not but for those that don’t have a reference point it may seem minimal. To me it’s a decent sized hole for any type of leakage but the key here is that Aeroseal’s main focus isn’t the size of the hole (you have bigger issues if your home has multiple holes larger than 5/8”) but the quantity of tiny holes. Just doing quick math, I would rather have 2-5/8″ then even just 25-1/16″ holes (25 is on the low end and there are likely more but just giving an example for frame of reference). While a single leak doesn’t seem like much, it all adds up quickly. When you think about the vast amount of duct connections and metal on metal joints you begin to understand just how much opportunity there is for duct leakage. All the connections along the trunk (transverse joints and longitudinal seams), the branches (joints where sections meet and where it connects to the trunk), boot to sheetrock or subfloor, connections with any equipment (whole home humidifiers for instance), elbows that change direction of flow, connections to dampers, and more really do add up.

This isn’t to say that mastic or duct tape couldn’t seal a good majority of the leaks but, the amount of time to do this manually may not be worth it plus many of these small leaks are either inaccessible or not apparent to the human eye and get skipped over. Would you rather settle on duct tape or mastic because it costs less upfront but still leaves you with more leakage than Aeroseal and will need to be reapplied due to its degradation which ends up costing you more or have guaranteed results with Aeroseal the first time which removes the risk of human error and seals the closest to 0% possible?